Custom Water Bottle & Tumbler Manufacturing Solutions

From product structure and materials to lids, surface finishes, logos, and packaging — all developed for stable mass production and brand consistency.

What Can Be Customized

Build a drinkware product that truly matches your brand. Choose from flexible customization modules below.

Customization Modules

Choose one module or combine multiple modules to build your ideal bottle or tumbler.

MODULE 01

Bottle Structure & Capacity Customization

- Capacity options (oz / ml), mouth size, bottle profile

- Stainless steel vacuum insulated, plastic, or glass solutions

- Designed for ergonomics, balance, and stable mass production

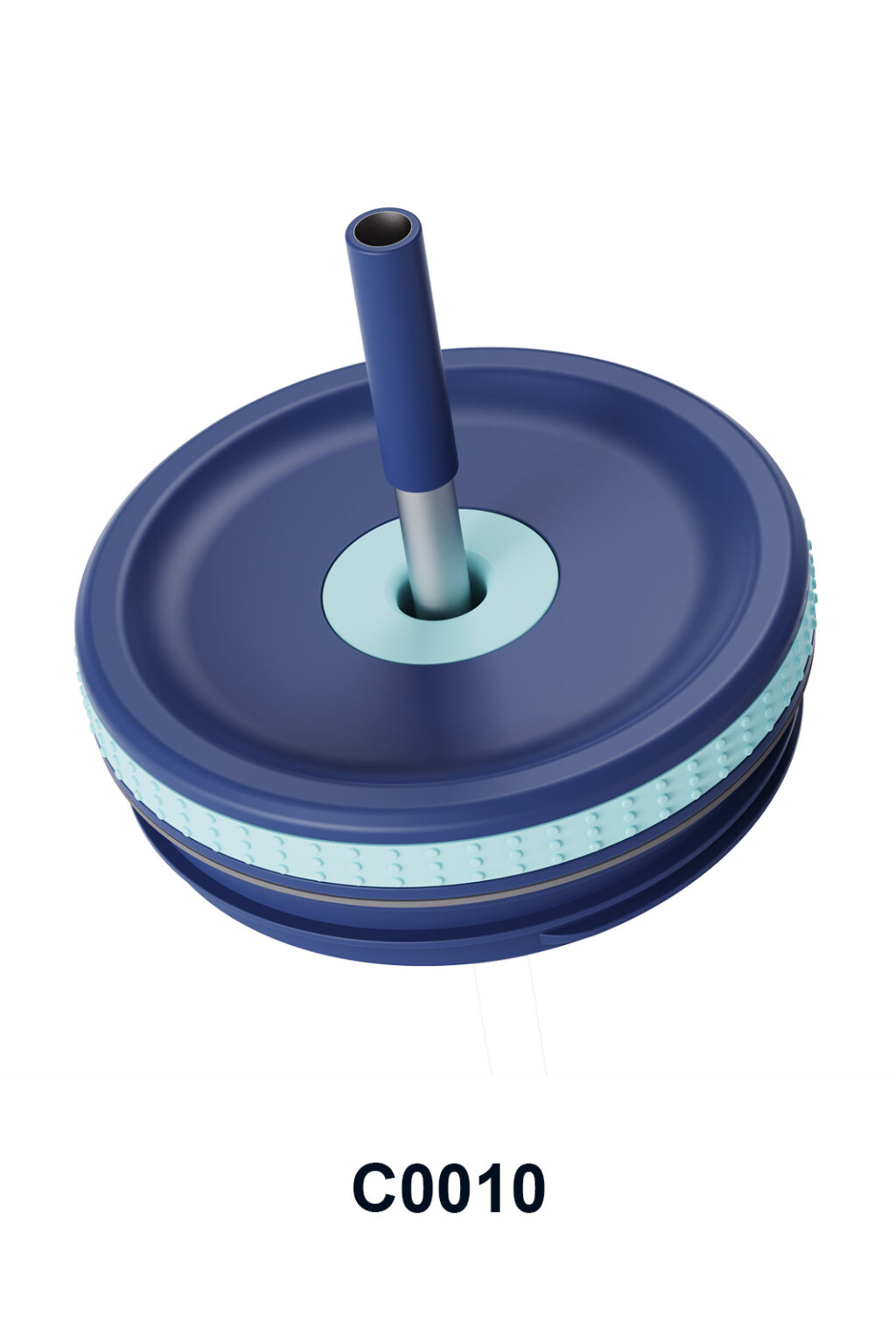

MODULE 02

Lids & Functional Accessories Customization

- Straw lids, sip lids, flip lids, screw lids, handle lids

- Leak-proof structures, vents, locking mechanisms

- Compatible with bottle size, mold structure, and production tooling

MODULE 03

Surface Finish & CMF Customization

- Powder coating, matte/gloss, rubberized feel, textures

- Color matching (Pantone), gradients, special effects

- Durability testing: adhesion, scratch resistance, corrosion resistance

MODULE 04

Logo Application & Artwork Support

- Laser engraving, silk screen, heat transfer, water transfer

- Placement options: body, lid, silicone parts, packaging

- Artwork review & production-ready file support (AI / PDF / EPS)

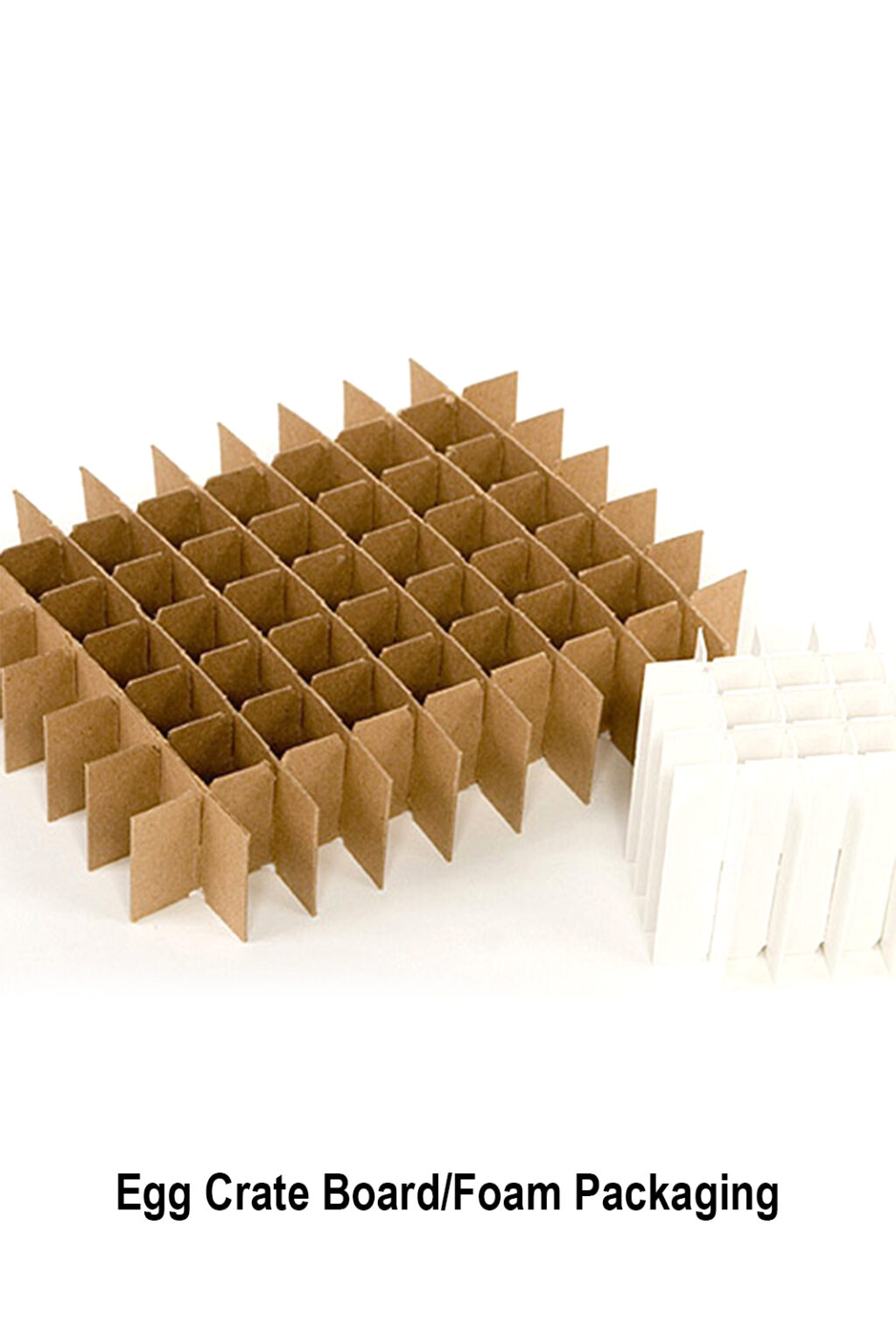

MODULE 05

Packaging & Compliance Customization

- Kraft box, color box, gift box, window options

- Inserts: foam, EVA, paper pulp, cardboard separators

- Manual, barcode, compliance marks for global markets

Our Customization Process

A clear, step-by-step OEM & ODM workflow — from concept validation to stable mass production.

1. Concept & Requirement Review

Product concept, target market & sales channel discussion

Capacity, structure, lid type, material selection

Feasibility evaluation for mass production

Initial cost estimate & MOQ alignment

2. Sample Development & Confirmation

Engineering drawings & structure optimization

Prototype or pre-production sample development

Logo, surface finish & color matching confirmation

Sample approval before tooling or bulk production

3. Pilot Run & Trial Production

Small batch pilot production before scale-up

Process validation & assembly verification

In-line functional & quality checks

Risk identification before mass production

4. Mass Production & Delivery

Stable mass production under confirmed standards

In-process QC & final AQL inspection

Packaging, labeling & compliance preparation

Shipment arranged according to agreed schedule

Quality Control Throughout Production

From incoming material inspection to in-line checks and final AQL inspection — every batch follows documented standards and traceable records.

Incoming Material Inspection

Stainless steel grade & thickness verification

Plastic & silicone material safety inspection

Coating powder & raw material batch traceability

Supplier qualification & incoming inspection records

In-Process Quality Control

Dimensional & assembly checks during production

Welding, polishing & surface finish inspection

Lid fitting, sealing & alignment verification

In-line functional testing by QC team

Final Inspection & Reliability Testing

- Leak-proof & sealing test

- Thermal insulation test

- Drop & impact resistance

- Salt spray / corrosion test

- Dishwasher durability (optional)

Custom Drinkware Manufacturing – FAQ

What types of drinkware can you customize?

We specialize in custom water bottles and tumblers, including stainless steel vacuum bottles, plastic bottles, glass bottles, and travel tumblers. Customization covers structure, capacity, lids, surface finish, logo, and packaging.

What is your minimum order quantity (MOQ)?

Our standard MOQ starts from 300 pcs per design, depending on product type and customization level. For new projects, we can discuss flexible solutions based on your development stage.

Can I get samples before mass production?

Yes. Pre-production samples are available for design confirmation, logo testing, and functional verification before bulk production begins.

Do you support OEM and ODM projects?

Yes. We support both:

OEM: Customize based on existing bottle models

ODM: Develop new structures, molds, or functional designs from concept to mass production

What logo printing methods do you offer?

We offer multiple logo methods including laser engraving, silk screen printing, heat transfer, water transfer, and embossed/debossed effects, depending on material and design requirements.

How long does custom production take?

Typical lead time:

Sample development: 7–15 days

Mass production: 30–45 days

Actual timing depends on order quantity, customization complexity, and production schedule.

How do you ensure product quality?

We implement full-process quality control, including incoming material inspection, in-line production checks, functional testing, and final AQL inspection to ensure consistent mass production quality.

Can you help with packaging design?

Yes. We support custom packaging solutions, including color boxes, kraft boxes, inserts, manuals, labels, and barcode compliance for different markets.

Are your products compliant with international standards?

Our materials and production processes comply with FDA, LFGB, and other relevant food-contact standards, depending on your target market requirements.

How do I start a custom project?

Simply submit your inquiry through the contact form with product type, quantity, target market, and customization needs. Our team will respond within 24 hours to guide you through the next steps.

Ready to Build Your Custom Bottle?

Share your product specifications and branding requirements.

Our team will review your request and provide a manufacturing solution and quotation.